What’s the gypsum powder?

Table of Contents

Description of gypsum powder

Gypsum powder can be divided into raw gypsum powder and cooked stone powder according to the different physical and chemical properties. It is widely used in many application fields.

Such as construction, building materials, industrial molds, and art models, chemical industry and agriculture, food processing, and medical beauty.

It is an important industrial raw material, usually white, colorless. Sometimes due to impurities in gray, light yellow, light brown, and other colors.

Physicochemical properties of gypsum powder

Name: Gypsum or Stucco (dihydrate gypsum, anhydrite, water gypsum, gypsum, chemical name dihydrate calcium sulfate)

Molecular weight: 172.17

Index of refraction: 1.52

Mohs hardness: 1.5~2

Toxicity: Non-toxic

Solubility: Insoluble in water, soluble in acid, ammonium salt, sodium thiosulfate and glycerol

Stability: when heated to 150℃, 1.5H2O will be lost to form a semi-aqueous substance (gypsum of Paris), and when heated to 163℃, all the crystal water will be lost to become anhydrous substance.

Under polarizing lens: colorless. Biaxial crystal (+). 2 v = 58. Ng=1.530, Nm=1.523, Np=1.521. 2V decreases with increasing temperature and reaches zero at about 90 ° C.

During heating, there are three stages of discharging water of crystal:

1.105~180℃, one water molecule is discharged first, and then half of the water molecule is discharged immediately, which is transformed into burnt gypsum, also known as plaster of Paris or hemihydrate gypsum.

2. At 200~220℃, the remaining half of the water molecules were discharged and converted into type ⅲ anhydrite.

3. About 350℃, transformed into type ⅱ gypsum Ca[SO4]. At 1120℃, it was further transformed into anhydrite type I. Melting temperature 1450℃.

The microporous structure of gypsum and its products and the heating of water, so that they have excellent sound insulation, heat insulation and fire performance.

The application of gypsum powder

Construction

A: Anhydrite cement and cementitious materials: anhydrite cement or cementitious materials can be produced by adding appropriate activators, which are suitable for soft soil foundation reinforcement, wall painting, mechanical modeling, tunnel support and fiber pressure plate production, etc.

B: It is used as a solvent and purifying agent in the glass production process.

C: Used as filler in plastics, rubber, coatings, asphalt, linoleum and other industrial production.

D: Concrete expansion agent, anti-cracking agent, self-leveling mortar main raw materials.

Chemical

A: It produces sulfuric acid and light cement.

B: It produces ammonium sulfate and light calcium carbonate.

Agricultural

A: To improve the soil, adjust the pH, suitable for the improvement of saline-alkali soil, red soil and other soil.

B: It is used as calcium and sulfur compound mineral fertilizer in edible fungus cultivation to adjust the pH of culture medium.

C: Used as compound mineral feed additive in poultry and livestock feed.

Anhydrite powder is packed in plastic woven composite bags, the size is 50±1Kg, and bulk and other specifications can be provided according to user requirements.

Anhydrite powder should be stored under ventilated and dry conditions.

Cathodic Protection

A: It is used as one of the filling materials for sacrificial anode. The general ratio is 75% gypsum powder, 20% bentonite, 5% sodium sulfate.

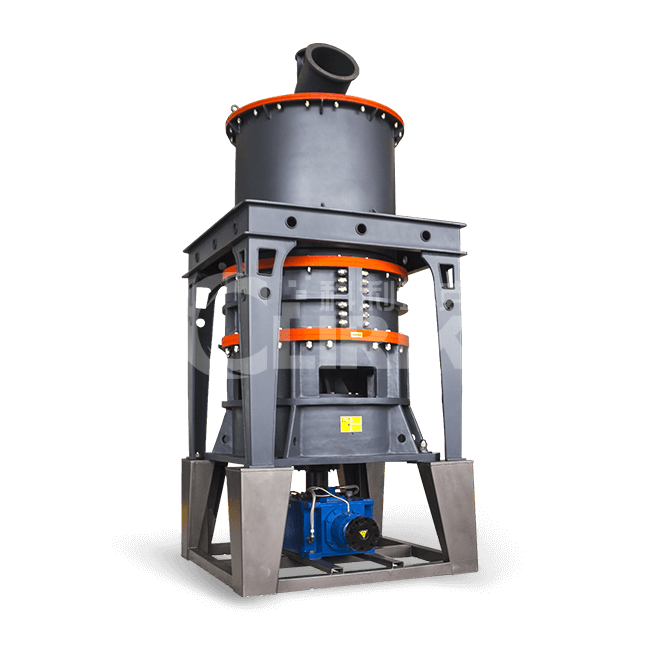

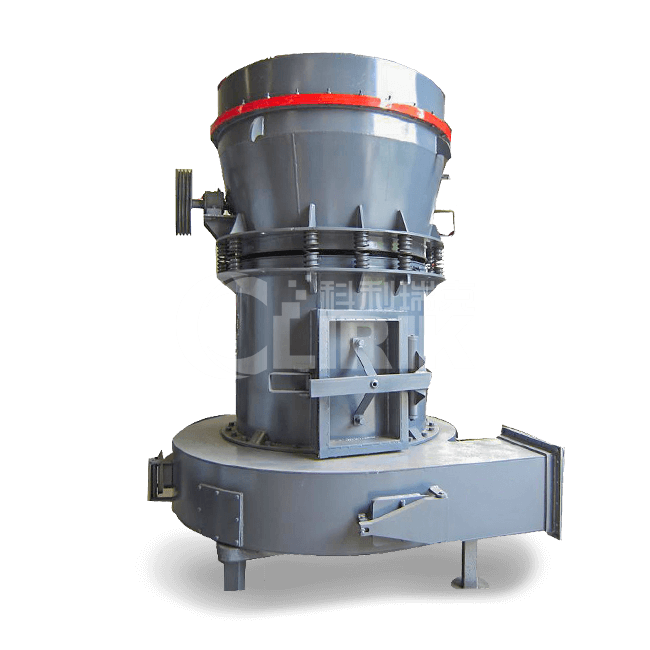

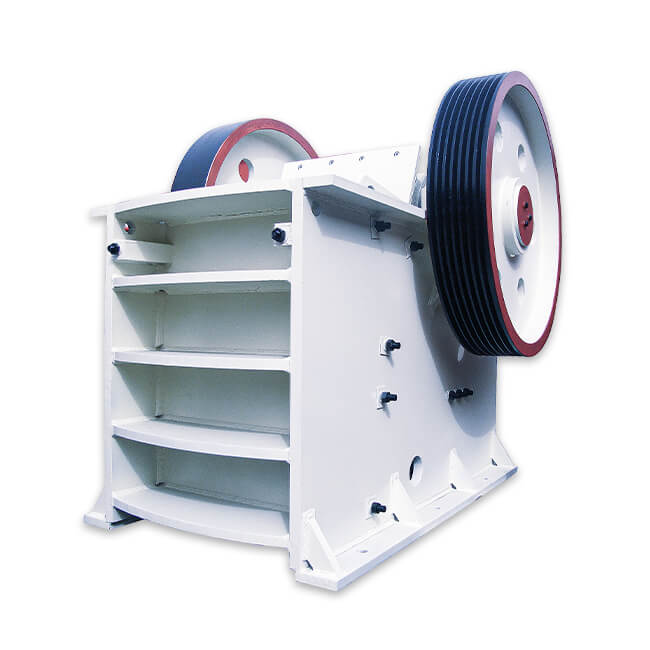

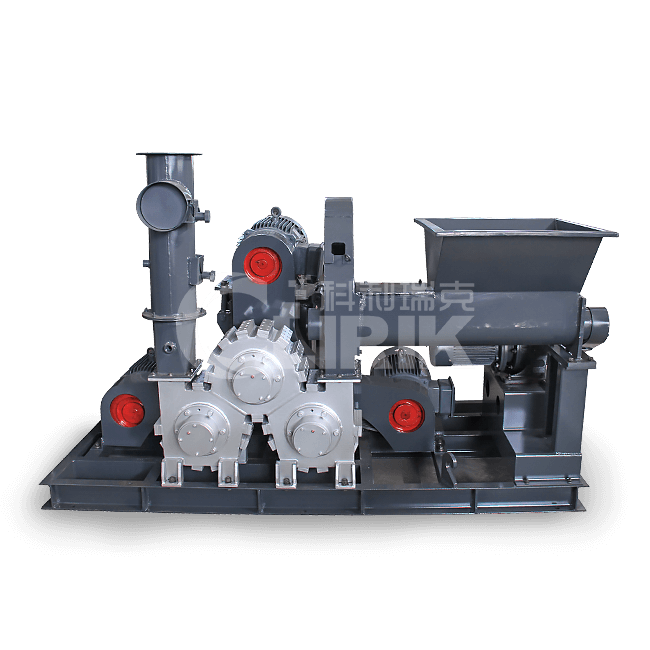

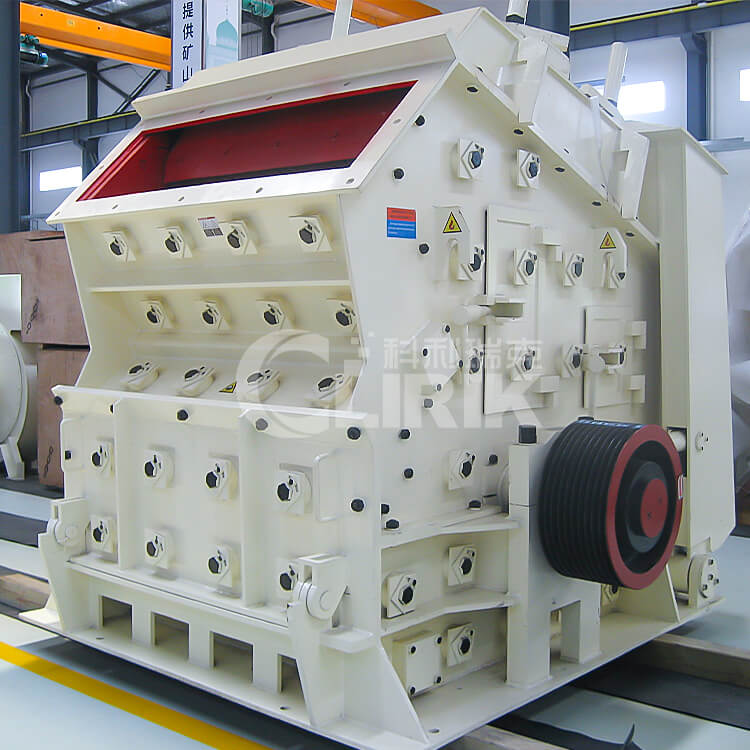

Recommended grinder products of gypsum powder

The following is the machine for processing gypsum powder. Different fineness corresponds to different grinding products. Please contact us for more details.

-

Previous:What is calcium carbonate?

Next:What is a limestone?