Old tires get new life – Clirik micro powder grinding mill

Table of Contents

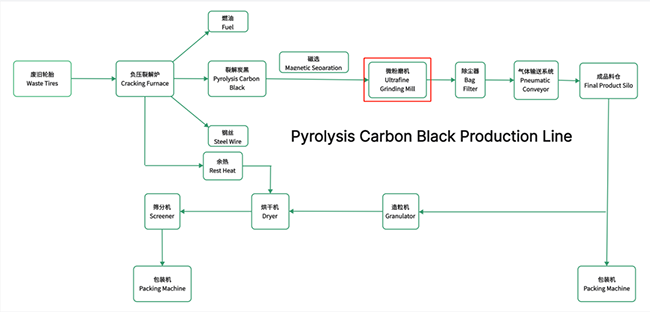

Refined carbon black after cracking waste tires

How to use a flour production line to match two or even multiple crushing production lines upstream of the industrial chain?

Equipment stability, quality of finished products, hourly output, annual capacity of several major conditions are indispensable.

Come to Clirik and find out!

The customer from Malaysia decided to use the HGM80 series micro powder grinding mill to achieve the production capacity target of “one production line fits two upstream production lines”.

Clirik teamed up with Malaysia’s environmental protection industry leader to expand the use of finished products in the tire cracking industry chain.

The two sides will work together to deepen the Southeast Asian market.

1. Refined carbon black is reused to make car tires, fan belts and printer toner.

2, recycled carbon black can be refined into nanoscale quality, replacing expensive raw carbon black, enabling manufacturers to provide cheaper alternatives and alternative products.

First acquaintance with Clirik

2021 is a special period when the epidemic is raging. After being introduced by peers, Malaysia’s leading domestic environmental protection company contacted Shanghai Clirik to express its willingness to cooperate on expanding the production of carbon black refined powder.

At that time, there was a lack of offline inspection conditions. Due to the recognition of the Clirik brand and the recommendation of local colleagues, the two parties subscribed for an HGM80 series ultra-fine grinding mill production line after only a few video conferences. 30 days later, a brand new small carbon black production line was delivered.

According to the customer’s requirements, the equipment is installed and put into production by the company’s equipment personnel. After the equipment has been running for a period of time, they communicated with our after-sales team in the hope of taking the existing production capacity to a higher level.

Service continues Clirik quality

In Clirik, the end of the contract between the parties in no way means the termination of the service:

The after-sales service team has rich production experience and records each customer’s situation to ensure timely response under any circumstances. In daily communication, the after-sales technical team adheres to the service concept of “continuing the entire life cycle of the equipment” and rushes to the production site as soon as possible after the epidemic is over to comprehensively optimize and upgrade the equipment.

Optimization content: Adaptive debugging of equipment parameters, unmanned configuration, feed fineness and other data.

Optimization:

- Upgrade and transform the equipment installation.

- Adjust relevant data parameters.

- The fan is equipped with a frequency converter to enable intelligent high and low pressure wind operation.

Establish a long-term mechanism:

- Provide detailed guidance to local company equipment managers on operational requirements and material feed fineness requirements.

- Record the operation status, wearing parts replacement cycle and other information in detail, and prepare a plan.

Cooperation makes Clirik brand

The Clirik HGM80 model production line is a small milling production line with a total length of only 15 meters, which can ensure that the fineness of the finished product is adjustable between 200-2500 mesh, and the 2μm content is nearly 70%. After optimization and upgrading, while maintaining high-quality output, production capacity has been further increased by 3-5% compared with before.

As a result, a single HGM80 micro powder grinding mill production line, with a host power of only 75KW, can provide an hourly output of more than 1 ton, and the annual output can exceed 5,000 tons. Compared with other types of grinding mills, the output has nearly doubled under the same generator power level; in terms of the fineness of the finished product, energy consumption has been reduced by more than 30%.

Small model creates large production capacity. The customer company is very satisfied with the equipment and praises: “The production capacity of this carbon black grinding production line alone is enough to adapt to the production capacity of our two tire pyrolysis production lines!”

Project information- Clirik micro powder grinding mill

Production line: HGM80 micro powder grinding mill production line

Processing materials: carbon black

Finished product particle size: 200-600 mesh

Annual production capacity: 6600 tons

Equipment configuration: 1 HGM80 host, 1 powder separator, 1 fan, 1 hammer crusher, 1 bucket elevator, 1 screw feeder, 2 discharge valves, 1 air compressor , 1 pulse dust collector.

Usage of finished products: sales of carbon black powder

Detailed explanation of production process – Clirik micro powder grinding mill

The loader transports the crushed ore with a particle size of less than 500 mm to the first-level vibrating feeder, and intelligently adjusts the feeding speed through the variable frequency motor to ensure that large pieces of ore are transported smoothly and evenly to the second-level vibrating feeder.

The ore will then be transported to the first-level jaw crusher to be crushed to less than 150 mm and fall evenly on the bottom belt conveyor. On-site staff are responsible for checking and screening out low-grade ore on the belt to effectively improve the whiteness and grade of the ore. After selection, it enters the secondary hammer crusher again for further fine crushing.

The ore finally enters the bottom vertical elevator, which lifts the material to the top of the silo and then transports it to the feed buffer bin of the grinding production line through the elevator. An electronic safety limit device is installed in the warehouse. The limit device will carry out intelligent full-time safety production monitoring. When the limit alarm occurs, the supply of raw materials needs to be replenished or stopped in time.

1. Energy saving and environmental protection:

- Negative pressure working system, the entire equipment is sealed;

- Gas conveying process, the finished products go directly into the large finished product warehouse

- Avoid dust spillage and ensure a clean production environment.

2. Finished product quality is stable:

- The residence time of materials in the mill is short, reducing repeated grinding.

- Ensure the particle size and chemical composition of the finished product, bringing more stable product quality.

3. Energy efficient:

- Special grinding structure to form an effective and stable material layer;

- The equipment has small vibration, the product is pollution-free and has good whiteness;

- Save 30% of electricity consumption compared with similar grinding mills.

4. All-weather operation capability:

- Reducer assembly: circulating oil lubrication system, circulating water cooling system;

- Ensure 24-hour uninterrupted production of the production line.

5. The equipment occupies a small area and facilitates site planning:

- The production line occupies a small area, saving industrial land area and reducing investment costs.

6. Design – production – full after-sales service:

- Collyric will provide customers with one-stop service, saving time and effort!