What is the talc powder?

Table of Contents

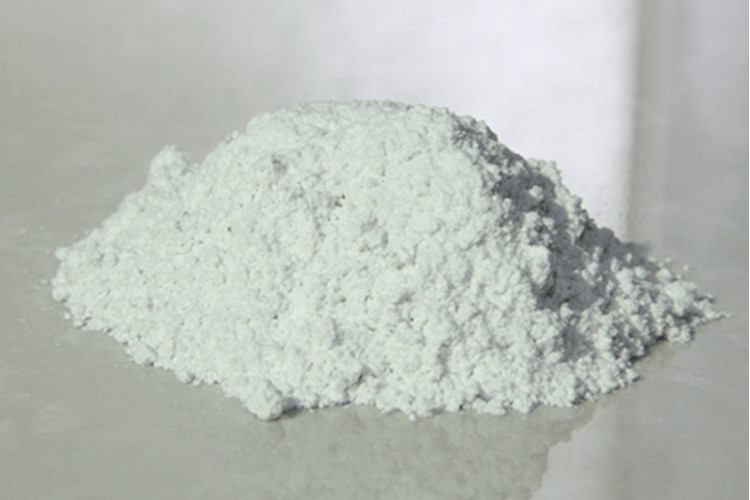

Introduction of talc powder

Talc main component is the aqueous magnesium silicate of talc, the molecular formula is Mg3Si4O102. Talc belongs to a monoclinic crystal system. Crystals are pseudohexagonal or rhomboid, occasionally seen. They usually form dense masses, blade-like, radial, and fibrous aggregates. Colorless transparent or white, but due to a small amount of impurities and appear light green, light yellow, light brown and even light red; the cleavage surface is pearl luster. Moh’s hardness 1~1.5, specific gravity 2.7~2.8, specific surface area 2.41-2.42 m2·g-1.

Talc has excellent physical and chemical characteristics such as lubricity, viscosity resistance, flow aid, fire resistance, acid resistance, insulation, high melting point, chemical inactivity, good covering power, softness, good luster, strong adsorption.

Types of talc powder

Chemical level

Application: Used in rubber, plastic, paint and other chemical industries as strengthening and improving filler. Features: Increase the stability of product shape, increase tension strength, shear strength, flexural strength, pressure strength, reduce deformation, expansion rate, thermal expansion coefficient, high whiteness, particle size uniformity and strong dispersion characteristics.

Ceramic grade

Application: Used in manufacturing high frequency porcelain, wireless electric porcelain, all kinds of industrial ceramics, building ceramics, daily ceramics and ceramic glaze. Features: no discoloration at high temperature, whiteness enhancement after forging and burning, uniform density, good gloss, smooth surface.

Cosmetics level

Usage: It is a high quality filler in the cosmetic industry. Features: High in silicon. It has the effect of blocking infrared rays, so it enhances the sunscreen and anti-infrared properties of cosmetics.

Medical food grade

Application: Used as additive in medicine and food industry. Features: non-toxic, tasteless, high white degree, good tolerance, strong gloss, soft taste, strong smoothness characteristics. The PH value is 7-9 and will not degrade the characteristics of the original product.

Papermaking grade

Application: Used in all kinds of high and low grade paper industry products. Features: Paper powder with high whiteness, particle size stability, low wear characteristics. The paper produced by using this powder can achieve paper smoothness, delicacy, save raw materials, improve the service life of paper.

Water magnesium powder

Uses: Used in manufacturing electric porcelain, wireless electric porcelain, all kinds of industrial ceramics, building ceramics, daily ceramics and ceramic glaze. Features: no discoloration at high temperature, whiteness enhancement after forging and burning, uniform density, good gloss, smooth surface.

Classified of talc powder

All kinds of talc is divided into three quality grades according to its physical and chemical properties: excellent, first-class and qualified products.

Specifications

According to the fineness and the passing rate of the screen, the ground talc powder is divided into the following two specifications:

A. Fineness 45μm, expressed as a percentage of product weight passing through the screen.

B. Fineness 75μm, expressed as percentage of product weight passing through the screen.

C. According to its particle size distribution and particle size composition, fine talc is expressed as the cumulative percentage of product less than 20, 10, 5, 2μm.

Product Labeling

The product marking of talc shall be indicated in the following manner:

Example 1: Paint grade talc with 75% whiteness and 45μm fineness passing 98%

Talcum powder TL75-45-98 gb

Example 2: fine talc powder with 80% whiteness, particle size less than 20μm and cumulative content more than 85%

Talcum powder WF80-20-85 gb

Example 3: Rubber grade talc with a fineness of 75μm and a passing rate of 99.9%

Talcum powder AJ75-99.9 GB

Applicaton of talc powder

Cosmetic grade

(HZ)

Talc powder used for all kinds of moisturizing powder, beauty powder, talcum powder.

Medicine-food grade (YS)

Talc powder Pharmaceutical tablets, pharmaceutical dispersions (such as acai powder) icing, prickly heat powder, traditional Chinese medicine prescriptions, food additives, isolation agents, etc.

Paint grade

(TL)

Talc powder is used for white constitution pigments and various kinds of water base, oil base, resin industrial coatings, primers, protective paints, etc.

Papermaking grade (ZZ)

Talc powder is used for all kinds of paper and board filler, wood asphalt control agent.

Plastic grade

(SL)

Talc is used for packing of polypropylene, nylon, polyvinyl chloride, polyethylene, polystyrene and polyester plastics.

Rubber grade

(AJ)

Talc is used for rubber filler and rubber products anti-stick agent.

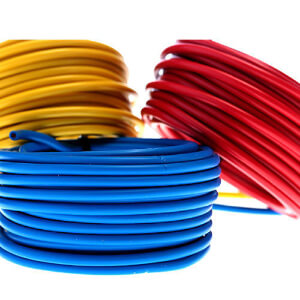

Cable grade

(DL)

Talc is used for cable rubber additive, cable isolation agent.

Ceramic grade

(TC)

Talc is used for manufacturing electric porcelain, wireless electric porcelain, all kinds of industrial ceramics, building ceramics, daily ceramics and porcelain glaze, etc.

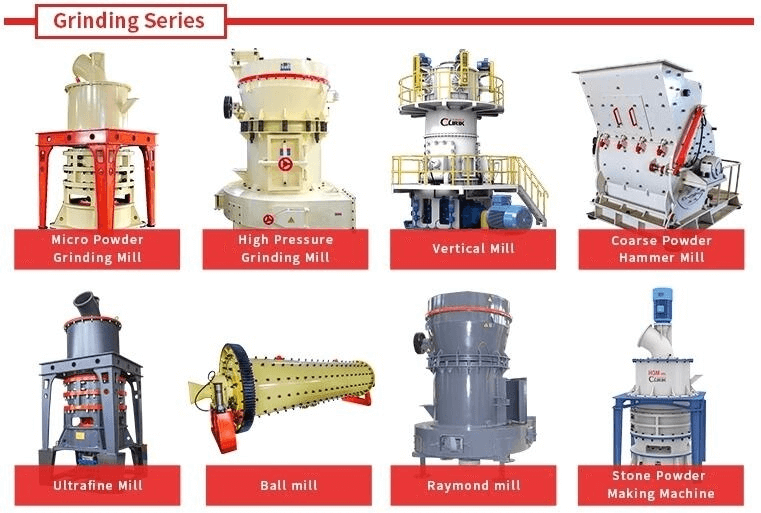

Processing machine of talc powder

About 90% of talc in the world are applied in the form of powder, so the processing and grinding of talc commonly used machines are talc crusher, Raymond mill, ultra-fine powder grinding mill, ultra-fine vertical powder grinding mill, modifying machine and other equipment.

High pressure suspension grinding mill and Raymond mill are suitable for processing talcum powder with large particle size, ultra-fine mill, ultra-fine vertical mill is predominantly used for processing talcum powder with small particle size. The modifier is used to modify the surface properties of talc powder so that it can be used in more fields.