The third phase of the project in Guangxi has finally landed.

Table of Contents

Project guide

Recently, the four additional HGM ultra-fine grinding production lines purchased last year by Clirik’s old customer in Hezhou, Guangxi were officially put into operation, helping the customer’s third-phase enterprise expansion plan. Up to now, the enterprise has put into operation a total of ten production lines of various types of Clirik, creating an output value of hundreds of millions.

Project cooperation list

As a local large-scale chemical material manufacturing and sales enterprise in Hezhou, Guangxi, the customer is a loyal user of Clirik ultrafine powder grinding mill. Up to now, the three-phase project of cooperation with Clirik has lasted for more than four years.

Since 2019, ten production lines of ultra-fine powder grinding mills and ultra-fine vertical roller mills have been ordered. The annual output of calcium carbonate ultra-fine powder alone has exceeded 500,000 tons, bringing an output value of more than one billion.

| Period | Selection production line | Order time | Delivery time |

| Phase I | Single CLUM-1425 Ultrafine Vertical powder grinding Mill | September 2019 | October 2020 |

| Phase I | Two HGM-125 ultrafine powder grinding mills | September 2019 | October 2020 |

| Phase II | Single CLUM-1425 Ultrafine Vertical Mill | January 2021 | November 2021 |

| Phase II | Two HGM-125 multi-head ultrafine powder grinding mills | May 2021 | November 2021 |

| Phase III | Two HGM-125 ultrafine powder grinding mills | February 2022 | August 2022 |

| Phase III | Two HGM-125 ultrafine powder grinding mills | February 2022 | March 2023 |

Details of this project

Production line: 2 HGM-125 upgraded ultrafine powder grinding mill production lines

Material Type: Calcium Carbonate Superfine Powder

Fineness requirement: 600-2000 mesh

The total annual production capacity of the third phase: 500,000 tons

Single equipment configuration: 1 HGM125 main engine, 1 multi-head powder separator, 1 powder separator, 1 fan, 1 hammer crusher, 1 bucket elevator, 1 feeder, 2 dischargers Valve, 1 air compressor, 1 pulse dust collector.

Finished product use: papermaking, paint, coating, filler, etc.

The refined powder production line that has been put into production was designed and manufactured by Clirik as a whole, and part of it adopts the upgraded version of ultra-fine powder custom production components equipped with multi-head powder classifiers.

Clirik Intensive Research: Multi-head powder separator to meet the customer’s positioning in the high-end powder market.

Different from the traditional ring roller mill, the main equipment equipped with multi-head powder separator will bring the overall production capacity and quality to a higher level, and the fineness of the finished product can jump from the original 325-1500 mesh to 1500-3000 mesh.

Project story-Stock of development, quality of transformation

Quick overview of the project: The client company has expanded from the first and second phase plans to open up the situation with quantity to the third and fourth phase plans to maintain production capacity and win through quality. Priority production in the early stage mainly focuses on the comprehensive preparation capacity of machines. Later, with the shift of the focus of the production strategy, the powder preparation line that specifically matched the downstream finished product industry was gradually developed.

1. The client company was originally engaged in the logistics industry and has accumulated extensive sales channel resources. After an in-depth investigation and investigation of the chemical powder industry, he was acutely aware of the broad market prospects of the downstream demand of the non-metallic ore powder making industry, and was determined to devote himself to the ultrafine grinding powder production and sales industry. After years of development, it is now a large-scale enterprise that manufactures and sells superfine powder.

2. With the development of production capacity and market demand, customers have higher and higher requirements for the fineness of finished product powders, and the transformation from medium and low-end powders to medium-end powders and high-end ultra-fine powders as a supplement The strategic transformation of “good quality war” focuses on improving the added value of finished products.

3. In the transformation of adapting to various downstream finished product markets, taking the additives of the paper industry as an example, in order to meet the high requirements of the industry for whiteness, fineness, and viscosity, the after-sales team carried out specific research on the grinding aids in the production line. Adjustment.

4. The official commissioning of this phase of the project marks the further deepening of the linkage with the downstream markets such as surrounding paper mills and paint factories, and the development of local industrial clusters will be promoted with a low-carbon and environmentally friendly closed-loop production and sales. Deepen and expand the future market with the strategic vision of radiating the whole country based on Guangxi. Completed the enterprise’s energy saving and emission reduction tasks, and successfully realized the synchronous improvement of local economic benefits, social benefits and ecological benefits.

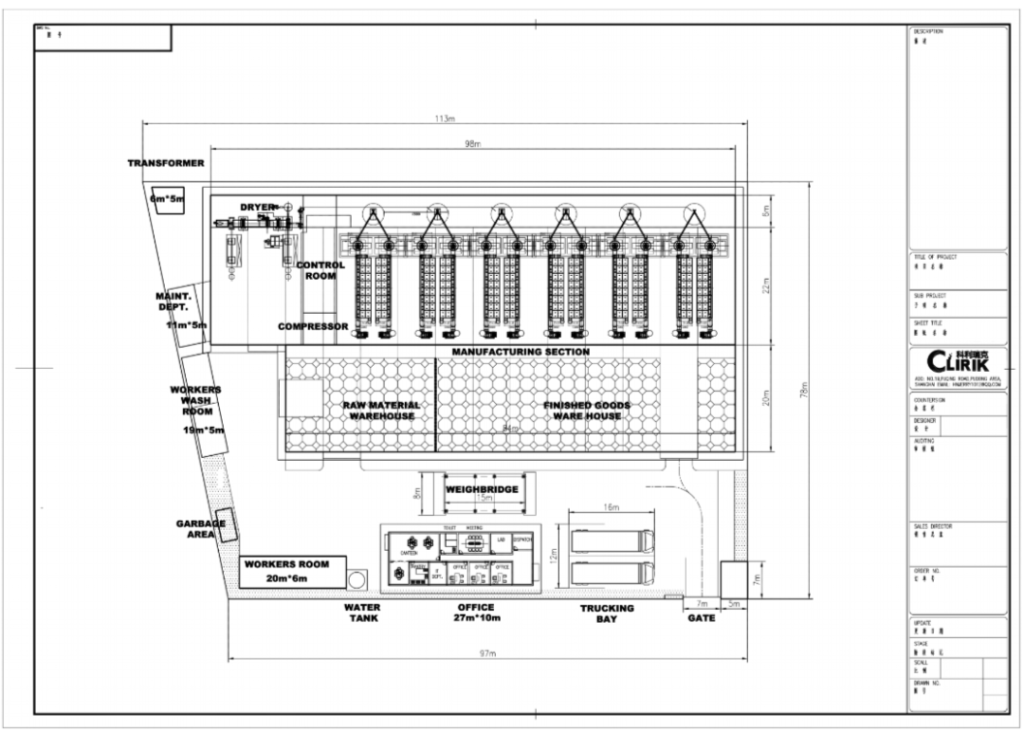

Plant area planning

Initial stage of the project: The project team rushed to the site for the first time, and designed a fully enclosed factory building based on the principle of reducing costs and increasing efficiency, combined with actual conditions.

Mid-term of the project: After the equipment is officially put into production, the after-sales personnel rush to the site again for connection and debugging. And provide relevant commissioning training for the equipment operators of the enterprise.

Later stage of the project: CliriK will also be equipped with equipment team personnel to stay locally to ensure that customers can worry-free after sales.

Advantages of Keli’s planning model: ensuring production line cost reduction and efficiency increase

(1) The production line is designed as a fully enclosed workshop, which can largely isolate dust and noise pollution during production;

(2) The production line is equipped with intelligent numerical control equipment to precisely control the fineness and output of finished powder, improving convenience and safety;

(3) The site is planned in an orderly manner in a straight line, which is convenient for later maintenance, and at the same time provides conditions for a single drive to run through the entire production site.

(4) The design of the negative pressure production chamber provides customers with green, safe, efficient and low-noise production requirements.