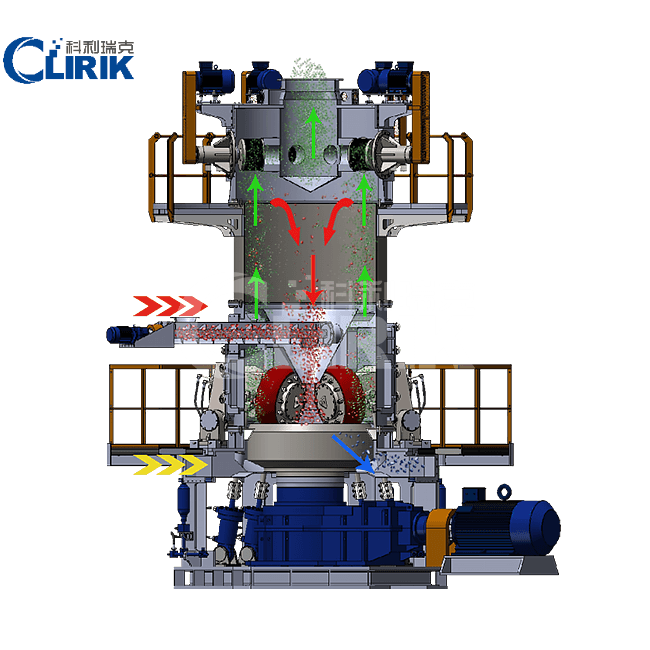

1. Strong product diversity.

Gypsum powder ultrafine vertical roller mill is equipped with turbine airflow classifier, which can produce large grain diameter, 2μm zone 30%~70%, D97=4~45μm, specific surface area 21000 cm²/ g, and D97=8.5μm products can be directly produced by the main machine.

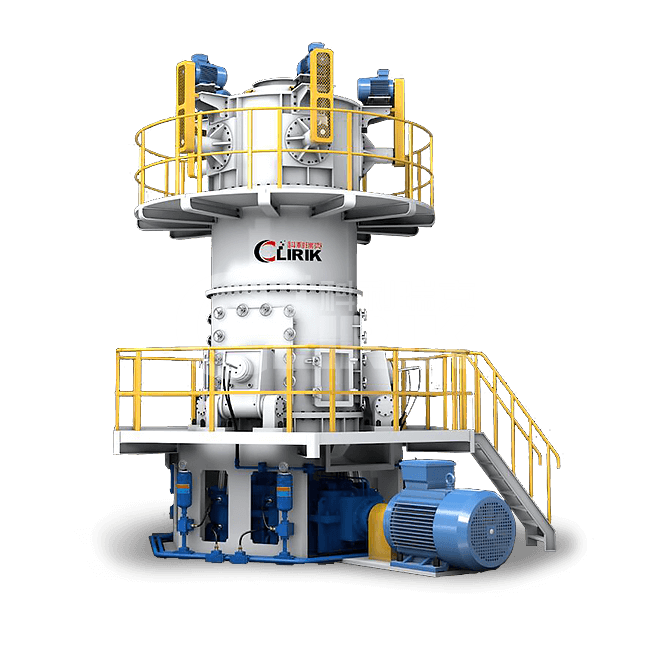

2. Adopt optimized design.

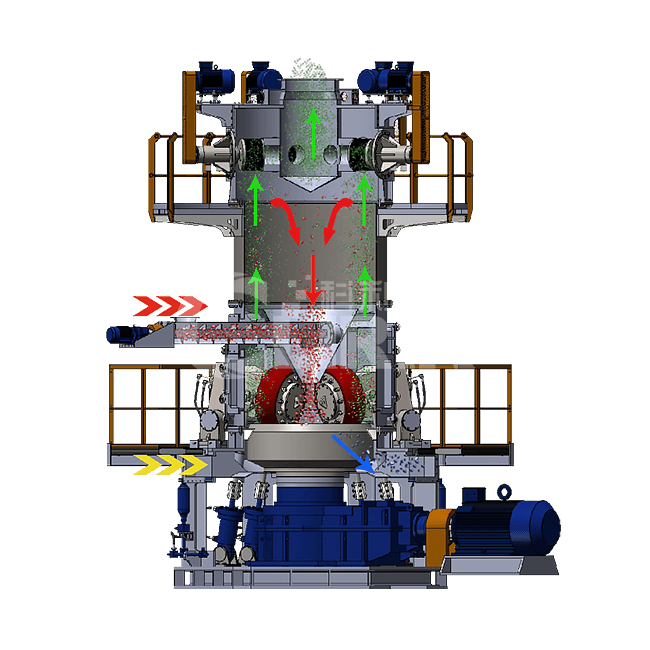

With optimized production line flow design, Gypsum powder ultrafine vertical roller mill consumes less energy than similar vertical mills.

3. It has a hierarchical function.

After grading, the ultrafine powder produced by the host has the advantages of narrow particle size distribution, adjustable and controllable 2μm content, high profit and added value of powder products, and good shape of single particle. Product diversity, competitiveness, can be used in a wide range of fields. Such as artificial granite, plastic masterbatch, PVC pipe, wire and cable, diapers, non-woven fabric and other industries. It has the advantages of good activation effect and low oil absorption value.

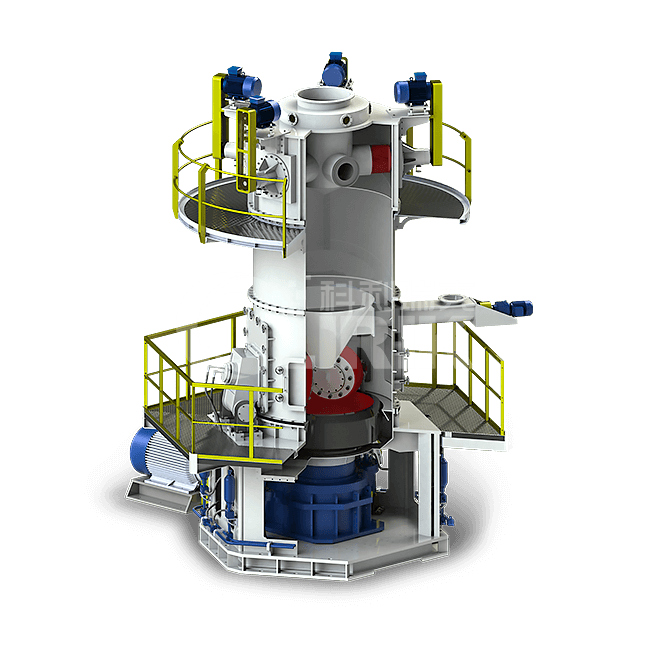

4. More robust performance.

The improved roller, mill disc, diversion system and internal circulation system greatly improve the grinding efficiency. Compared with the same type of products, the output is 15%~30% higher, and the power saving rate is 30~60% compared with the ball mill and other equipment.

5. Industry-leading technology.

Advanced grinding equipment technology, improved grinder, can operate under low vibration, compared with Taiwan or domestic brands, Gypsum powder ultrafine vertical powder grinding mill noise is lower.