CLQM series airflow vortex mill

Processing ability: 10-5000 kg/h

Fineness: 50 - 8000mesh

Max feeding size: 20-100 cm

Range of application: Stone Ores,Chemicals, Food products, PVC and other materials.

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: 10-5000 kg/h

Fineness: 50 - 8000mesh

Max feeding size: 20-100 cm

Range of application: Stone Ores,Chemicals, Food products, PVC and other materials.

Table of Contents

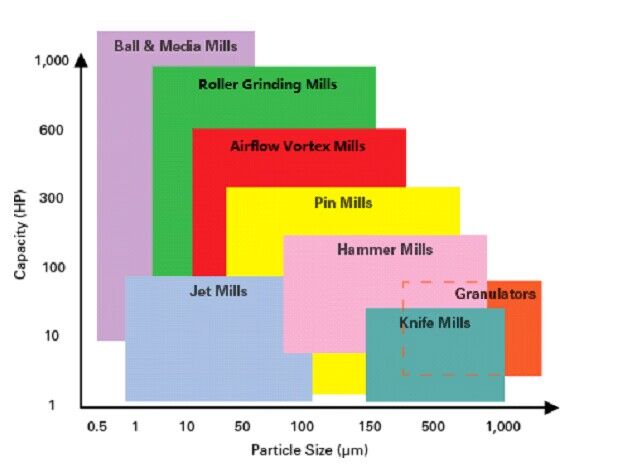

CLQM series airflow vortex mill (jet mill) is one of today’s most widely used grinding machines for reducing dry fine chemicals, food products, and other materials. It combines a mechanical impact mill with dynamic air classifier for middle-small volume continuous processing. After several years experience, it can be customized to different materials.The mill can be equipped with different grinding tracks as well as different impact elements, depending on the product and final product specs.

With over 1000 references worldwide, it is used the most industry:

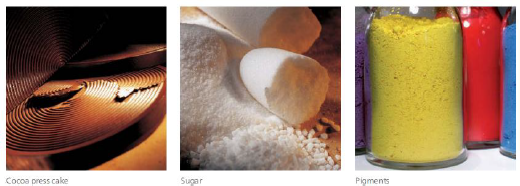

1. Chemicals: Bisphenol, tartaric acid, E-PVC, fungicides, herbicides, stearates.

2. Powder coatings: Epoxy, polyester, hybrids, UV-curing acrylates, polyamide.

3.Food: Sugar, cacao, starch, fish meal, xanthan, guar flour, lactose.

4. Pharma/cosmetics: Face powder, ascorbic acid, tartaric acid.

5. Minerals: Talc, kaolin, calcium sulphate, bauxite, limestone.

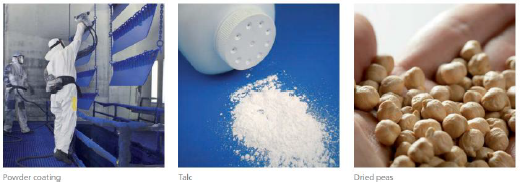

MAIN STRUCTURES

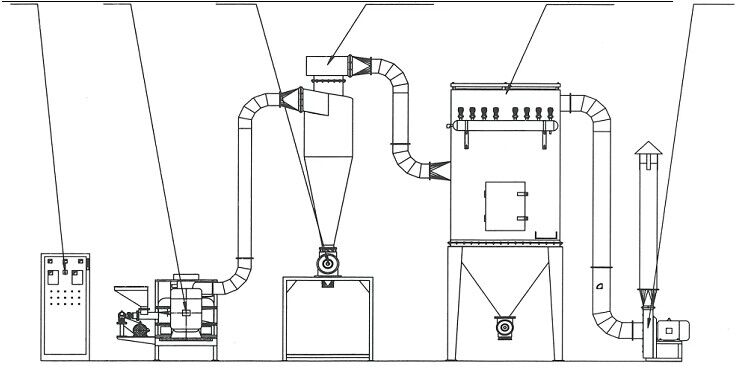

CLQM series airflow vortex mill mainly consists of the screw feeder, grinding unit, classifier, power section, cyclone, filter, blower, electrical panel etc. The main motor, mill disc, mill blocks, classifier, inlet liner, main shaft, mill baffle.

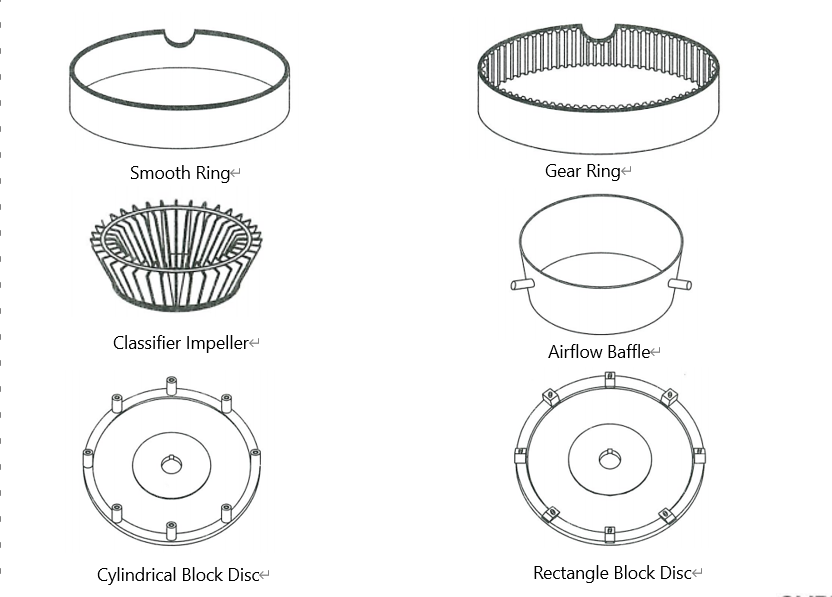

Main unit components:

1. Unit base

2. Lower body

3. Main bearing assembly

4. Middle body

5. Fixed blocks

6. Mill disc

7. Airflow baffle

8. Classifier impeller

9. Upper cover

10. Outlet hole

11. Classifier bearing assembly

12. Hopper

13. Feeding part

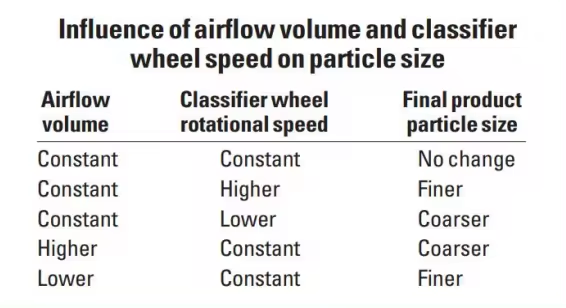

The material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating grinding disc. At the same time, it is subjected to centrifugal force and collides with the grinding ring gear, and is subjected to various comprehensive forces such as shearing, friction and collision to finished grinding. The grinded material moves to the classifying zone with the airflow. The classifier is adjusted by frequency conversion, separates the coarse and fine materials, the product that meet the fineness requirement enters the cyclone collector and the dust collector with the airflow, and the coarse powders return to the classifying zone, secondary grinding.

TECHNICAL ADVANTAGE

1. Muti-function combination: cooling, drying, grinding and classifying.

2. Different types of grinding disc (pin, hammer, teeth or others) are used based on characteristics of materials to obtain different grinding forces and improve grinding efficiency.

3. Key parts like the hammer, gear ring and classifying wheel are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product.

4. Compact structure and small occupation, easy to disassemble and clean.

Parameter 1

| Model | Motor(kw) | Rotated Speed(rpm) | ||||

| Main Unit | Classifier | Feeder | Main Unit | Classifier | Feeder | |

| CLQM-15 | 7.5 | 0.75 | 0.55 | 7000 | 800-3000 | 20-100 |

| CLQM-20 | 11 | 1.1 | 0.55 | 5500 | 750-3100 | 20-100 |

| CLQM-30 | 22 | 4 | 0.55 | 4000 | 700-2800 | 20-100 |

| CLQM-45 | 30 | 5.5 | 0.55 | 3500 | 650-2600 | 20-100 |

| CLQM-60 | 45 | 7.5 | 0.55 | 3000 | 600-2400 | 20-100 |

| CLQM-100 | 55-75 | 11 | 1.1 | 2000 | 500-2000 | 20-100 |

| CLQM-125 | 90-110 | 15 | 1.1 | 1600 | 400-1600 | 20-100 |

Parameter 2

| Model | Diameter of rotor disc (mm) | Diameter of gear ring (mm) | Diameter of classifier (mm) | Linear speed of the outermost end of the rotor disc (m/s) | Air volume (m³/h)(max) | Product fineness (μm) | Output (kg/h) | Main Unit Dimension (L*W*H mm) |

| CLQM-15 | 300 | 366 | 175 | 110 | 700-1200 | 3-300 | 10-200 | 1450*900*1000 |

| CLQM-20 | 300 | 366 | 175 | 87 | 1300-2800 | 5-300 | 20-600 | 1450*900*1000 |

| CLQM-30 | 400 | 470 | 242 | 84 | 2200-3600 | 5-300 | 30-1000 | 1740*1190*1100 |

| CLQM-45 | 550 | 601 | 274 | 102 | 3600-6500 | 10-300 | 40-1200 | 1940*1250*1170 |

| CLQM-60 | 700 | 774 | 350 | 110 | 4000-7500 | 10-300 | 50-1500 | 2150*1460*1380 |

| CLQM-100 | 1000 | 1080 | 414 | 106 | 8000-12000 | 10-300 | 80-3000 | 2840*2150*1760 |

| CLQM-125 | 2000 | 1295 | 461 | 101 | 12000-16000 | 10-300 | 120-5000 | 3000*2380*2000 |

Manufacturer profile of CLQM series airflow vortex mill:

About Company

Shanghai Clirik Machinery Co., Ltd. has a professional technical force and perfect production capacity. The company’s products are widely used in mining, road construction, bridge construction, housing construction and other industries,micro powder grinding mill, crusher, modified machine, ball mill, feeder, vibrating screen, sand washing machine, conveyor and other equipment and products. All passed ISO9001:2008 standard quality certification.

Clirik is a scientific and technological enterprise specializing in the research, development and production of industrial powder making, construction sand making and mining crushing equipment. It is a mining technical equipment manufacturer, located in the core economic zone of the Yangtze River Delta with convenient water, land and air- Shanghai. It is a technical enterprise that effectively combines science and technology with traditional technology.

Research and Development

Shanghai Clirik Machine Co., LTD., founded in 2010, currently has more than 200 scientific research and production engineers, and owns a number of mill, crusher, coating machine, sand machine patents. Clirik has established contact with many scientific research institutes at home and abroad to seize the commanding heights of industry technology. The company pays attention to scientific research investment, and the annual R&D investment accounts for more than 30% of the company’s profits. Scientific research engineers through Solidorks, CAD, CAE, Matlab simulation analysis and other computer aided design software, for product research and development, design, production in every detail to provide a guarantee, to ensure the accuracy and perfection of products, improve the overall reliability.

Manufacturing Processes

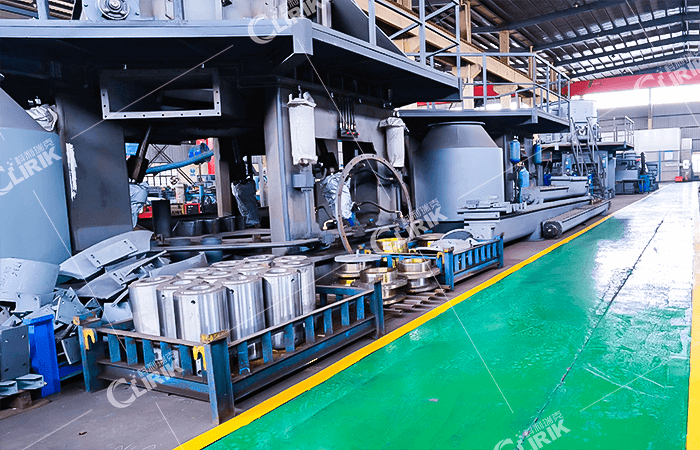

Clirik has more than 12,000 square meters of standardized production plant, including a processing workshop, assembly workshop, painting and sandblasting workshop, trial machine debugging workshop, finished product placement workshop, etc. The workshop is equipped with more than 100 high-end CNC machine tools of well-known foreign brands. From drawing, assembly to debugging, the equipment manufacturing has gone through thousands of processes, including resizing, cutting, grinding, trimming, heating, forging, turning, milling, grinding and drilling, inspection, painting, assembly and test machine. Each manufacturing process is repeatedly verified by our engineers to ensure the reliability and integrity of each device. Raw materials are related to the quality of products. Our engineers have strict requirements on the selection of raw materials. International standard steel is used.

1. who are we?

We are based in Shanghai, China, start from 2010,sell to Mid East(30.00%),Africa(20.00%),Southeast Asia(19.00%),South Asia(15.00%),North America(3.00%),South America(3.00%),Domestic Market(3.00%),Southern Europe(2.00%),Eastern Europe(00.00%),Eastern Asia(00.00%),Western Europe(00.00%),Central America(00.00%),Northern Europe(00.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.what can you buy from us?

Ball Mill, crusher and other needed machines in the stone powder production line project.

4. why should you buy from us not from other suppliers?

1. CE, ISO9001 2. factory sell directly 3. 30 years experience, professional 4. Sales market all over the world 5. good after sales serive

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CPT,DDU,Express Delivery;

Accepted Payment Currency: USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken: English,Chinese,French