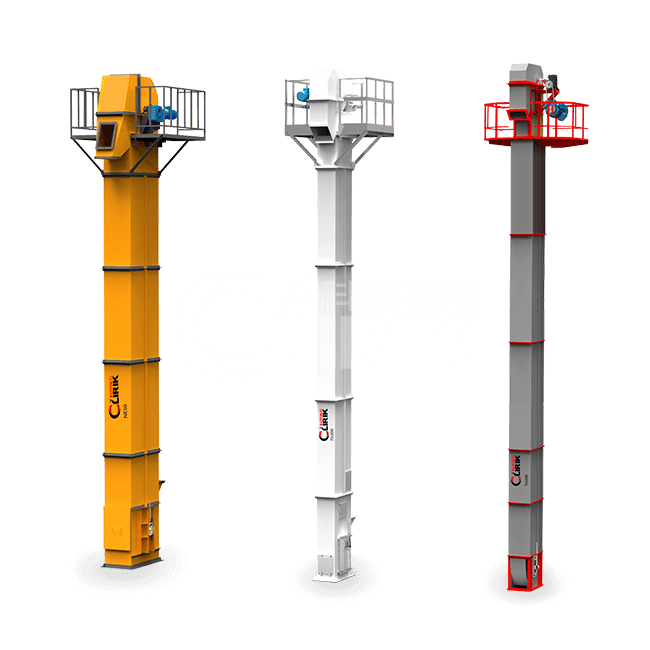

TH Bucket Elevator

Processing ability: 15.77-210 m³/h

Fineness: /

Max feeding size: 30-60mm

Range of application: Ore、 Coal、 Cement Chamotte、Foodstuff ...

- +8613917147829

- sales@clirik.com

Focus on the field of micro powder grinding !

Processing ability: 15.77-210 m³/h

Fineness: /

Max feeding size: 30-60mm

Range of application: Ore、 Coal、 Cement Chamotte、Foodstuff ...

Table of Contents

Product introduction of TH bucket elevator

The TH bucket elevator is a kind of vertical conveying equipment, widely used in conveying powder, granule and small lump of no rub or small rub (material temperature under 250 ℃), such as coal, cement, gravel, sand, fertilizer, food, etc. The main performance and parameters meet JB3926-85 vertical bucket elevator; the round-link chain accords with MT36-80 mineral high strength round-link chain.

Product features of TH bucket elevator

1. High capacity. The capacity is 1 times higher than the HL bucket elevator in the same bucket width.

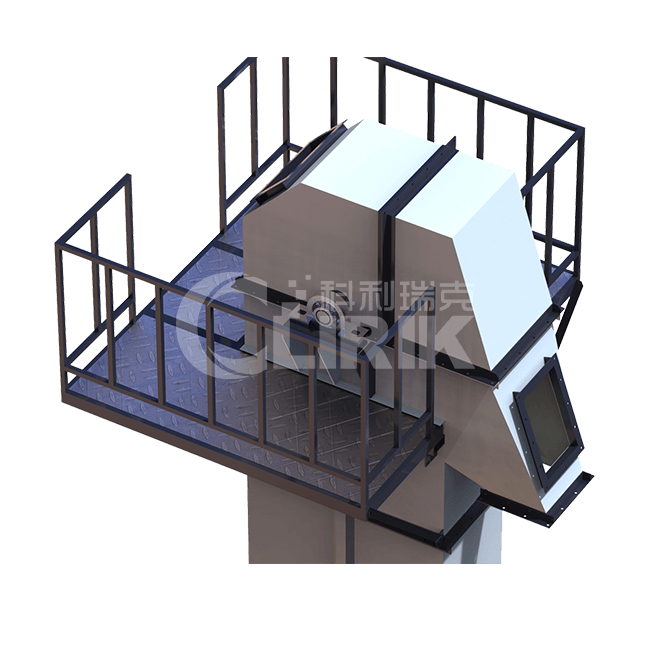

2. Adopt packaged sprocket, consisted of wheel body, sprocket rim which are connected by high strength bolt. It is convenient to unscrew the bolt and change sprocket rim after the sprocket wheel wear to a certain degree, which can save material, reduce the maintenance costs.

3. The heavy-duty lever tensioning device makes automatic tension be realized. Once installed, no need to adjust, and it can keep constant tension, ensure the normal operation and avoid the skid or take off the chain.

4. Stable lifting height, reliable operation, low noise, easy maintenance.

5. The conveying capacity of improved model is 30% higher than normal models.

6.The drag part is high strength low alloy steel chain whose lifetime is long. After proper heat treatment, the steel chain has very high tensile strength and wears resistance.

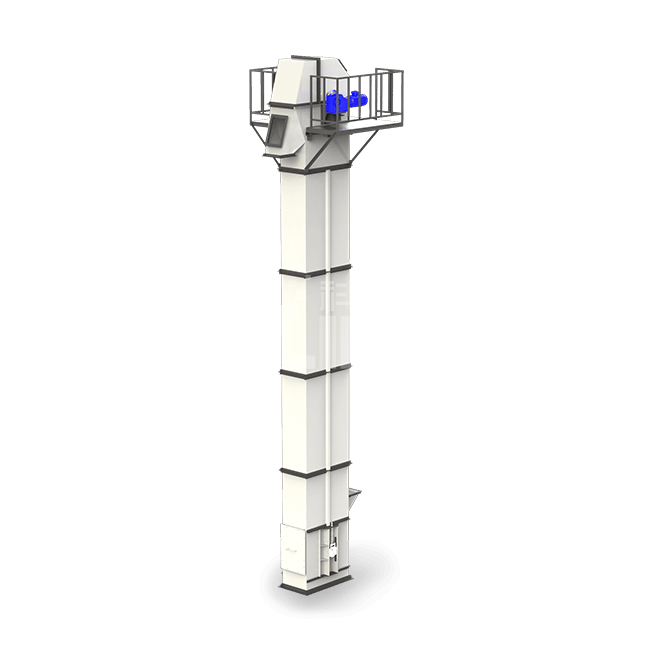

Working principle of TH bucket elevator

The TH bucket elevator consists of frame, drag part (conveyor chain), hopper, drive wheel (head wheel), feeding inlet (input inlet) and discharging outlet (output outlet). The materials get into the bottom of the elevator through chute, then scooped up by hoppers and elevated to the top along with the conveying chain. After get round the top wheel, the materials turn down into the discharging outlet, thereby conveyed to the required position. The whole process is accomplished inside the frame, preventing the dust floating.

The drag part uses high strength high quality alloy steel chain. Sprocket wheel with the sprocket rim composite structure has long lifetime and easy to replacement. The lower part using the gravity automatic devices can keep constant tension force, avoid skid or take off the chain and get certain yieldability, effectively protect lower shaft parts and other parts when hoppers get stuck accidentally.

Product specification of TH bucket elevator

Parameter 1

|

Link Chain Bucket Elevator Model |

TH160 |

TH200 |

TH250 |

||||

|

Hopper Type |

ZH |

SH |

ZH |

SH |

ZH |

SH |

|

|

Capacity/(m³/h) |

15.77 |

24.97 |

17.87 |

28.6 |

31.43 |

48.19 |

|

|

Hopper |

Volume (L) |

1.2 |

1.9 |

1.5 |

2.4 |

3.0 |

4.6 |

|

|

Interval (mm) |

500 |

|||||

|

Chain |

Round Steel Diameter*Pitch(mm) |

14*50 |

|||||

|

|

Single Load(KN) |

≥190 |

|||||

|

Hopper Running Speed/(m/s) |

1.2 |

1.2 |

1.2 |

||||

|

Drive Sprocket Rotation Speed(r/min) |

69.71 |

63.22 |

44.11 |

||||

|

Conveying largest size(mm) |

20 |

25 |

30 |

||||

Parameter 2

|

Link Chain Bucket Elevator Model |

TH315 |

TH400 |

TH500 |

TH630 |

|

|||||||

|

Hopper Type |

ZH |

SH |

ZH |

SH |

ZH |

SH |

ZH |

SH |

|

|||

|

Capacity/(m³/h) |

35 |

59 |

58 |

93 |

81 |

130 |

145 |

210 |

|

|||

|

Hopper |

Volume (L) |

3.75 |

6 |

5.9 |

9 |

9.3 |

15 |

15 |

24 |

|

||

|

Interval (mm) |

512 |

688 |

|

|||||||||

|

Chain |

Round Steel Diameter*Pitch(mm) |

φ18*64 |

φ22*86 |

|

||||||||

|

Single Load(KN) |

≥320 |

≥480 |

|

|||||||||

|

Hopper Running Speed/(m/s) |

44 |

37.6 |

39.7 |

35.8 |

||||||||

|

Conveying largest size(mm) |

35 |

40 |

50 |

60 |

||||||||

In addition to TH bucket elevator, we have many other mine production equipment for you to choose from.

Processing ability: 1-45 t/h

Fineness: 150-2500 mesh

Max feeding size: 10-25mm

Processing ability: 1-30t/h

Fineness: 50-325 mesh

Max feeding size: 20mm

Processing ability: 1-20 T/H

Fineness: 150-3000 mesh

Max feeding size: <10 mm

Manufacturer profile of TH bucket elevator

About Company

Shanghai Clirik Machinery Co., Ltd. has a professional technical force and perfect production capacity. The company’s products are widely used in mining, road construction, bridge construction, housing construction and other industries,micro powder grinding mill, crusher, modified machine, ball mill, feeder, vibrating screen, sand washing machine, conveyor and other equipment and products. All passed ISO9001:2008 standard quality certification.

Clirik is a scientific and technological enterprise specializing in the research, development and production of industrial powder making, construction sand making and mining crushing equipment. It is a mining technical equipment manufacturer, located in the core economic zone of the Yangtze River Delta with convenient water, land and air- Shanghai. It is a technical enterprise that effectively combines science and technology with traditional technology.

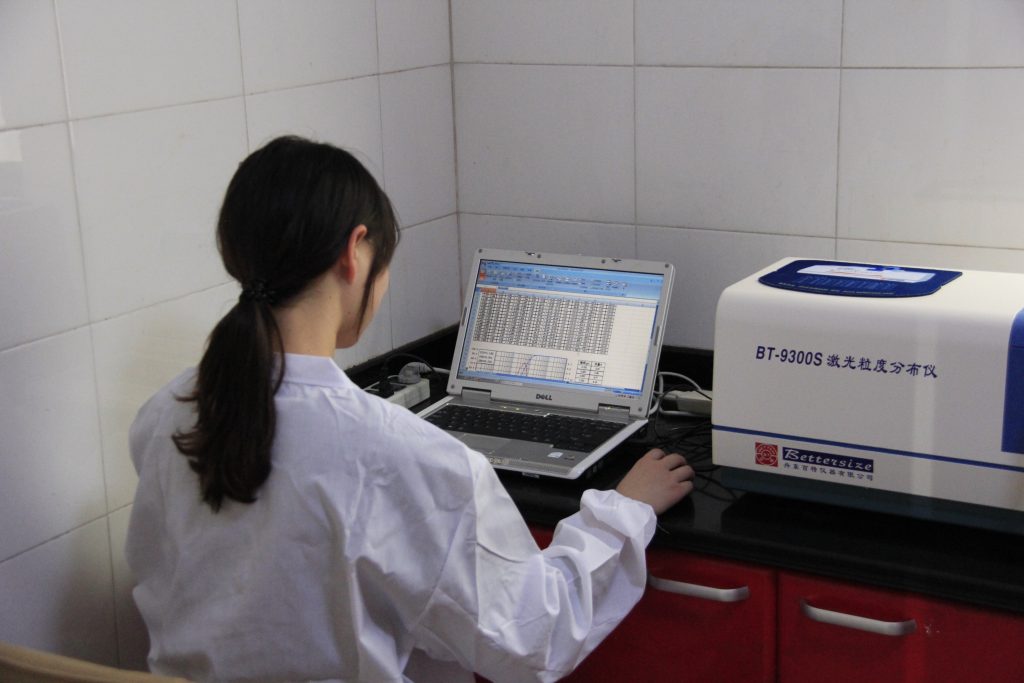

Research and Development

Shanghai Clirik Machine Co., LTD., founded in 2010, currently has more than 200 scientific research and production engineers, and owns a number of mill, crusher, coating machine, sand machine patents. Clirik has established contact with many scientific research institutes at home and abroad to seize the commanding heights of industry technology. The company pays attention to scientific research investment, and the annual R&D investment accounts for more than 30% of the company’s profits. Scientific research engineers through Solidorks, CAD, CAE, Matlab simulation analysis and other computer aided design software, for product research and development, design, production in every detail to provide a guarantee, to ensure the accuracy and perfection of products, improve the overall reliability.

Manufacturing Processes

Clirik has more than 12,000 square meters of standardized production plant, including a processing workshop, assembly workshop,

painting and sandblasting workshop, trial machine debugging workshop, finished product placement workshop, etc. The workshop is equipped with more than 100 high-end CNC machine tools of well-known foreign brands. From drawing, assembly to debugging, the equipment manufacturing has gone through thousands of processes, including resizing, cutting, grinding, trimming, heating, forging, turning, milling, grinding and drilling, inspection, painting, assembly and test machine. Each manufacturing process is

repeatedly verified by our engineers to ensure the reliability and integrity of each device. Raw materials are related to the quality of products. Our engineers have strict requirements on the selection of raw materials. International standard steel is

used.

1. How long is the warranty of your TH bucket elevator? Do you supply spare parts?

Our warranty period is generally one year. We can supply spare parts.

2. Do you provide after-sale services?

Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

3. Do you provide TH bucket elevator operation training?

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

4. Are you a trading company or manufacturer?

We are a factory.

5. How long is your delivery time?

Generally, it is 10-15 days if the goods are in stock.

or it is 15-20 days if the goods are not in stock, it is according to quantity.

6. If I need a complete crushing plant, can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We have already built many mining projects in China & overseas.