|

Model

|

GZ1

|

GZ2

|

GZ3

|

GZ4

|

GZ5

|

|

Input capacity (t/h)

|

5

|

10

|

25

|

50

|

100

|

|

Max input size(mm)

|

50

|

60

|

70

|

100

|

150

|

|

Motor power (W)

|

60

|

150

|

200

|

450

|

650

|

|

Voltage(V)

|

220

|

|

Current(A)

|

≦1

|

≦2.8

|

≦3.8

|

≦7

|

≦10.6

|

|

Double-amplitude(mm)

|

1.75

|

|

Bottom clearance(mm)

|

1.9-2.2

|

|

Weight (kg)

|

73

|

155

|

225

|

460

|

656

|

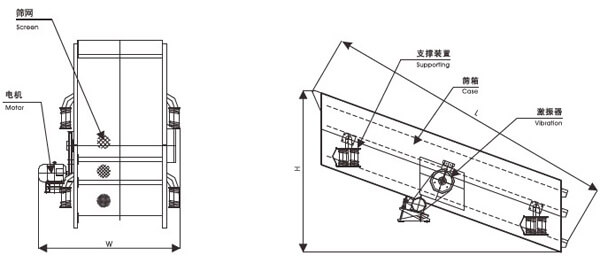

Product Overview

GZ Vibrating Feeder is a kind of linear direction feeding equipment. It features smooth vibrating, reliable operation, long service life and being suitable for feeding. They are widely used in mining, building-material, silicate and chemical industry in the crushing and screening plants. In the Sand-Stone production line, it can send materials to crusher evenly and continuously and at the same time, it can screen materials roughly.

Product Advantage

1. Be applied to kinds of rock, especially suitable for viscous material; and can be work in dust condition or water more environment.

2. Enclosed body structure, prevent dust pollution.

3. Equipped with double eccentric shaft as vibration source, stable amplitude guarantee the stable flow of vibrating material.

4. Less wearing parts, low power consumption of vibration, significant energy save.

5. The gap between grizzly bars can be adjusted to customer’s requirement, thus screen the material primarily.

Working Principle

GZ Vibrating Feeder is consisting of feeding trough, vibrator, spring set, transmission device and so on. The vibrating source is the vibrator, which is made of two eccentric shaft and gears. The motor dives the key shaft by triangle belt; then the gears in the key shaft joggle the driven shaft to rotate, the key shaft and the driven shaft rotate in the opposite direction at the same time. Thus the trough is vibrated; material is conveyed to required place continuously.

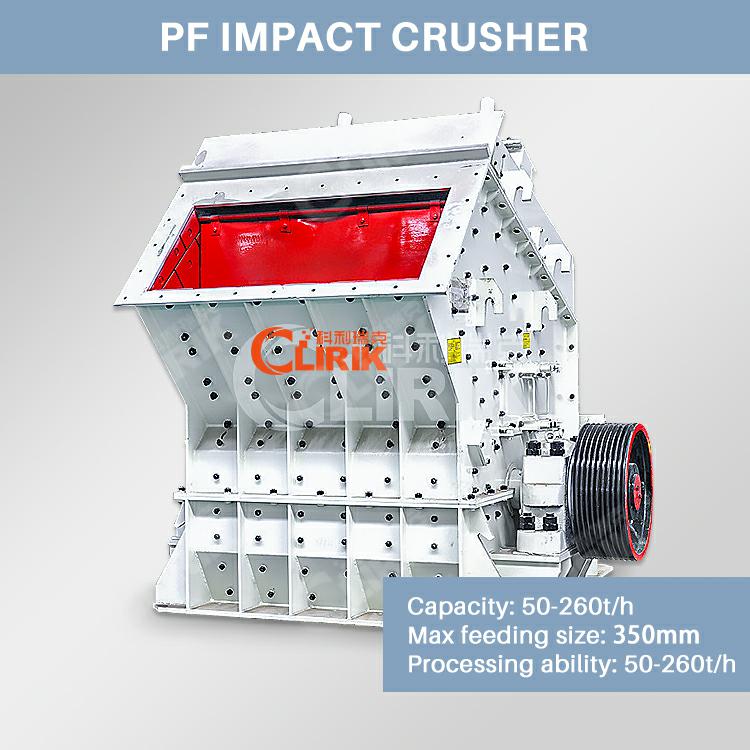

Other Products Offered