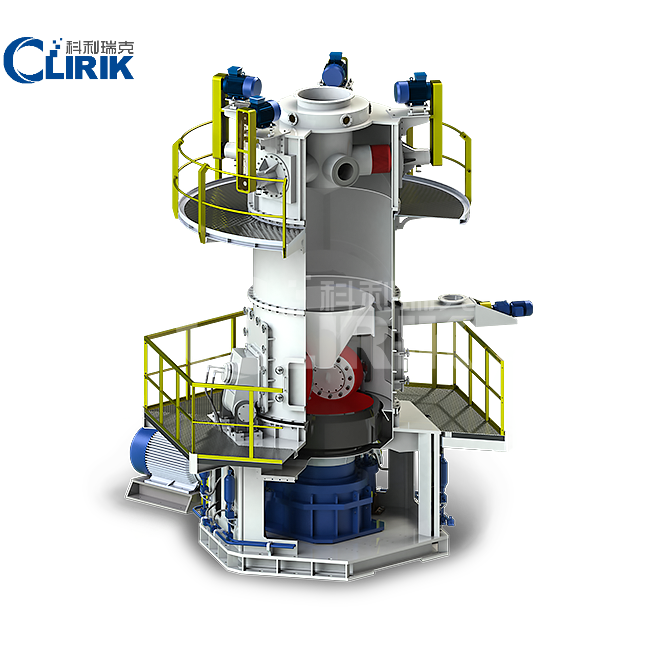

Product Overview

With the rapid development of society and economy, in the field of ultra-fine powder processing, in the face of more and more application requirements for ultra-fine powder, traditional ultra-fine powder processing equipment has been difficult to meet market demand due to its generally low production capacity. The low production capacity has seriously restricted the development of modern ultrafine powder processing enterprises. In response to the current market demand, Shanghai Clirik combined with years of experience in the production of pulverizers, introduced the ultrafine vertical mill technology from Taiwan and Germany, and designed and developed a set of grinding mills.

CLUM1425 ultrafine vertical powder grinding mill, a new type of ultra-fine grinding equipment integrating grading, conveying, secondary powder selection and finished product packaging, the product fineness can reach 400-3000 mesh, breaking through the low production capacity of ultra-fine powder processing After 5 years of hard work, Clirik Ultrafine Vertical Powder Grinding Mill has built 30 ultrafine powder production lines around the world.

CLUM1425 ultrafine vertical powder grinding mill can be widely used in chemical, metallurgy, non-metallic ores and other industries, especially in the field of ultra-fine grinding of white non-metallic ores. Rubber, PVC, ink and other industries provide high-quality fillers and additives. It can be widely used in large-scale ultra-fine dry powder processing of non-metallic minerals such as calcite, marble, limestone, dolomite, barite, talc, kaolin, dolomite, wollastonite, gypsum, feldspar, and pyrophyllite.

Product Parameter

| CLUM1425 Ultrafine Vertical Powder grinding Mill |

| Fineness Size(mesh) |

D97 (μm ) |

2μm content % |

Capacity (t/h) |

D50 (μm) |

D100 (μm) |

| 600 |

21-25 |

28-32 |

9.5-10.5 |

5.7-5.3 |

46-50 |

| 800 |

16-20 |

33-37 |

7-8 |

4.3-4.7 |

36-40 |

| 1000 |

14-12 |

38-42 |

5.5-6.5 |

2.8-3.2 |

29-33 |

| 1250 |

9.5-11.5 |

43-47 |

4.5-5.5 |

2.2-2.6 |

21-25 |

| 1500 |

7.5-9.5 |

48-52 |

3-4 |

1.8-2.2 |

16-20 |

The raw material processed by the equipment is marble.

Feed size <=10mm, CaCO3>=98%, moisture <=3%, MgO<=0.3%, SIO2<0.3%. Grinding aids can be added as needed during operation ,The equipment capacity testing instrument is based on the general Mode of Dandong Baxter particle Size distribution Analyzer (particle refractive index 1.529) |

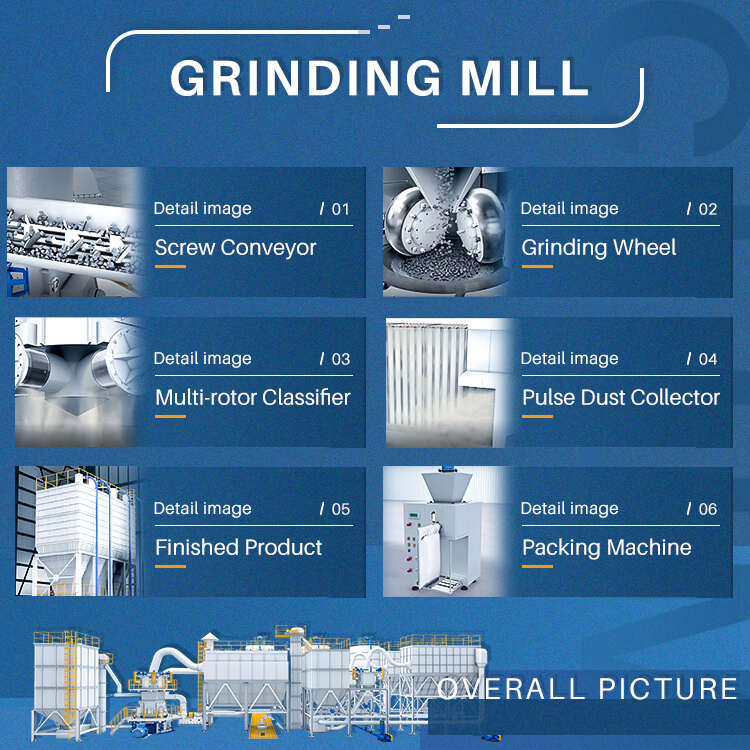

Working Principle

CLUM1425 ultrafine vertical powder grinding mill mainly consists of the motor,reduction gear,grinding rollers,grinding plate,pressure-applying device,classifier,mill body.oil station ,and electrical system.

CLUM1425 ultrafine vertical powder grinding mill plate is rotated by the main motor via the reduction gear. Meanwhile ,high pressure air enters the mill interior via inlet. Materials then fall onto the center of the grinding plate in rotation by the screw conveyor feeder.Due to the centrifugal force,the materials evenly move from the center of the grinding plate towards its fringe. While passing across the track in the grinding plate,large blocks of materials are crushed and grinded directly by the grinding roller.the fine particles form the material bed ,owing to squeezing ,where the inter-particle crushing takes place until grind to the fine powder.

CLUM1425 ultrafine vertical powder grinding mill fine powder continue to move towards the fringe of the grinding plate until they are taken away by strong air flow at the air ring.While the materials along with the air flow pass through the separator located above the grinding plate,the coarse particles return to the grinding plate for re-pulverization due to the action of the rotor blade,the fine particles along with the air flow leave the mill interior and are collected and discharged as finished powder product by the powder collector.

Performance Advantage

- High efficiency and energy saving

When the fineness of finished product and the power of motor are the same, the output is more than twice higher than that of air mill, mixing mill and ball mill.

- Wearing parts have long service life

The grinding roller and grinding ring are forged by special materials, so that the utilization degree is greatly improved. Generally can be more than a year, processing calcium carbonate, calcite, the service life can be up to 2-5 years.

- High safety and reliability

Because there is no rolling bearing and no screw in the grinding chamber, there is no problem that bearings and seals are vulnerable, and there is no problem that screws are easy to loose and destroy the machine.

- Environmental protection and cleaning

Pulse dust collector is used to capture dust, muffler is used to reduce noise, with environmental protection, clean characteristics.

Company Profile

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill, European version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on.Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front.

1. One year guarantee for whole machine except for wear parts.

2. 24 hours technical support .

3. Calling service .

4. User manual available .

5. Reminding for the service life of the wearing parts .

6. Installation guide for clients from both China and abroad .